Hydrocarbons such as oil & gas are primarily found in deep sedimentary formations of fractured limestone and sandstone. Contrary to popular belief, they are not necessarily in vast pools underground. Rather, they are found within the pockets of rock formations spread over vast geographic areas.

Porosity & Permeability are the keys to recovering this oil and gas.

All stones have pores and capillaries in which liquids may be held. Porosity refers to the rock’s ability to store liquid hydrocarbons and is measured as a ratio of open spaces to sold material. A good way to understand porosity is to compare a piece of traditional lava rock to a piece of granite. The lava rock is filled with holes and cavities while the granite appears completely solid. Of course, the lava rock has the potential of holding a greater quantity of liquid, thus it has a higher porosity.

All stones have pores and capillaries in which liquids may be held. Porosity refers to the rock’s ability to store liquid hydrocarbons and is measured as a ratio of open spaces to sold material. A good way to understand porosity is to compare a piece of traditional lava rock to a piece of granite. The lava rock is filled with holes and cavities while the granite appears completely solid. Of course, the lava rock has the potential of holding a greater quantity of liquid, thus it has a higher porosity.

The pores and capillaries of rock may be interconnected. This interconnectedness allows liquids to flow more freely in, around, and through the rock. The measure of this flow-ability is referred to as Permeability. To successfully recover oil & gas, hydrocarbon reservoirs must have both a high degree of porosity and substantial permeability.

The pores and capillaries of rock may be interconnected. This interconnectedness allows liquids to flow more freely in, around, and through the rock. The measure of this flow-ability is referred to as Permeability. To successfully recover oil & gas, hydrocarbon reservoirs must have both a high degree of porosity and substantial permeability.

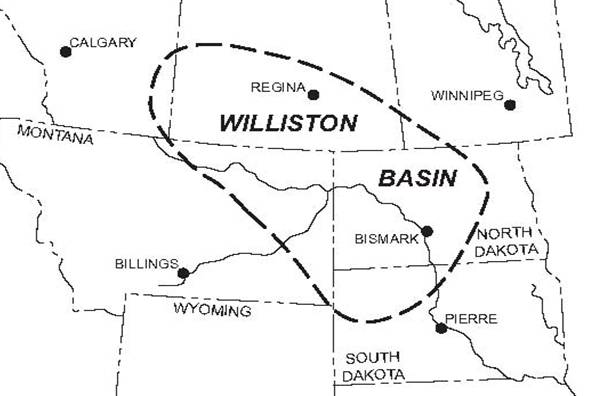

The Williston Basin is a large geographic area covering portions of North & South Dakota, Montana, and Saskatchewan. At nearly 300,000 square miles, the Williston Basin is significantly larger than Texas.

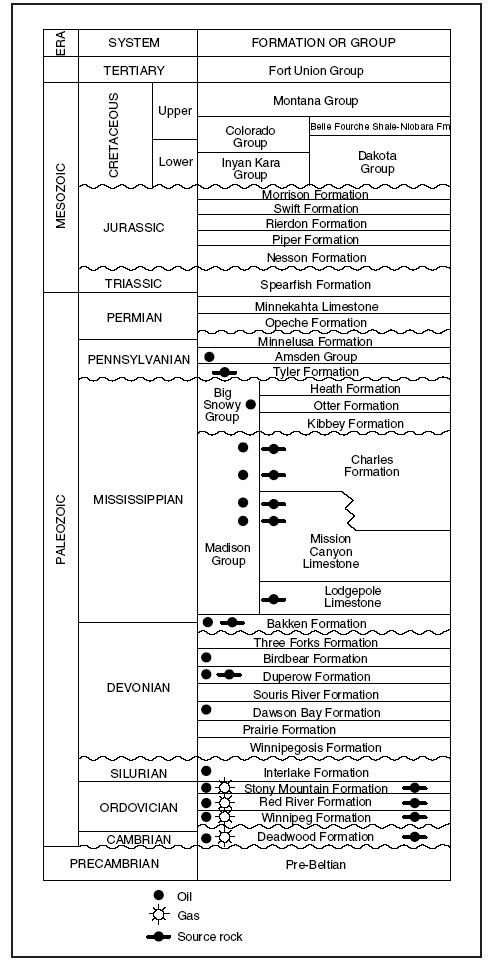

Williston Basin Stratigraphic Column

Williston Basin Stratigraphic ColumnThe Stratigraphic Column of the Williston Basin shows the different geological formations found at various depths in the region. The most productive layers recently have been the Bakken and Three Forks formations. However, there is now renewed interest in the Spearfish formation, and continuing interest in the Lodgepole, Mission Canyon, Birdbear, and Red River formations.

The BakkenThe Bakken has been the most notable formation in the Williston Basin. Its exploration began in the 1950s, however, recent advances in exploration techniques coupled with higher crude oil prices have resulted in substantial improvement in oil recovery in this area.

In 2008, the U.S Geological Survey (USGS) reported up to 4.3 billion barrels of recoverable oil are stored in the Bakken formation. The State of North Dakota estimates up to 40 years of drilling activity will be required to tap this reserve.

What Are My Options As A Mineral Owner?

When the landman calls, you have two options. You may sign an oil & gas lease, or participate in the well.

Why Lease?When you lease, you are basically assigning your rights to explore for minerals to us for a stated term. You are relieved of the liability and costs of drilling and operating the well in exchange for a smaller percentage of the gross production. You will also receive an upfront bonus payment which is based on the amount of mineral acres you own. Whether or not the well is ever drilled, or whether or not it is successful, you get to keep the bonus payment.

The cost of drilling and fracturing a horizontal well into the Bakken formation is typically $3 million to $4 million, but can cost $9 million or more. To make this large investment feasible, we must accumulate as much leasehold interest as possible. Otherwise, the well may never be drilled.

Participants are essentially partners in the well. They receive a larger portion of the gross production, but also accept a proportionate share of the costs and liability. Participating is generally not recommended unless you have access to geological data, the history of other wells in the area, knowledge of drilling practices, and experience with the high-pressure legal and regulatory labyrinth associated with oil exploration. Drilling is a high-stakes game. It requires a significant investment and carries a substantial risk.

What Is Pooling And Spacing; Will My Well Drain Oil From My Neighbor’s Land?

Spacing Units are tools used to prevent the drainage of oil & gas from nearby lands, and to prevent over drilling of a particular field. When a well is proposed, a Spacing Unit will be assigned by the state regulatory agency. The default spacing unit for new horizontal wells in most areas of the Williston Basin in North Dakota is now 1,280 acres. However, it is not uncommon to also find spacing units of 640 acres, 320 acres, or even smaller. Recently, North Dakota and several other states and provinces have been experimenting with 2,560 acre units. These super units may be evolutionary to oil & gas exploration and often require upfront permitting of multiple wells from a single drill pad. This is thought to increase efficiency of land use, pipelines, and utilities.

Within this Spacing Unit, companies must follow rules regarding the number of wells to be drilled and their locations. Everyone owning minerals within the Spacing Unit is pooled together and will share in the gross production of the well based on their percentage ownership. For example, if you have 160 net mineral acres and the Spacing Unit is 1,280 acres, you own 12.5% of the Spacing Unit. This type of pooling is fairer to your neighbors. It prevents drillers from locating their wells on adjacent property lines in order to drain oil from the land nearby. It also discourages the competitive drilling of too many wells. This can reduce the overall pressure of the field thereby lowering the total amount of recoverable oil.

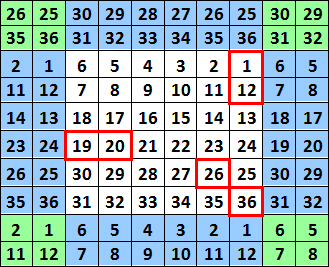

1,280-acre Spacing Units are described as stand-up, lay-down, or diagonal. A stand-up Spacing Unit is generally two full adjacent sections from north to south. A lay-down Spacing Unit refers to two full adjacent sections side by side, east to west. Although rarely used, a diagonal Spacing Unit exists where two full sections touch only at one corner.

1,280-acre Spacing Units are described as stand-up, lay-down, or diagonal. A stand-up Spacing Unit is generally two full adjacent sections from north to south. A lay-down Spacing Unit refers to two full adjacent sections side by side, east to west. Although rarely used, a diagonal Spacing Unit exists where two full sections touch only at one corner.

The Township Chart (right) illustrates the different Spacing Unit types. Sections 1 and 12 comprise a Stand-Up Spacing Unit. Sections 19 and 20 demonstrate a Lay-Down Spacing Unit. Sections 26 and 36 represent a Diagonal Spacing Unit.

| North Dakota | North Dakota Industrial Commission, Oil and Gas Division | |

| Montana | Montana Board of Oil and Gas | |

| South Dakota | South Dakota Department of Environment and Natural Resources | |

| Wyoming | Wyoming Oil & Gas Commission | |

| Manitoba | Manitoba Ministry of Innovation, Energy, and Mines | |

| Saskatchewan | Saskatchewan Ministry of Energy and Resources |

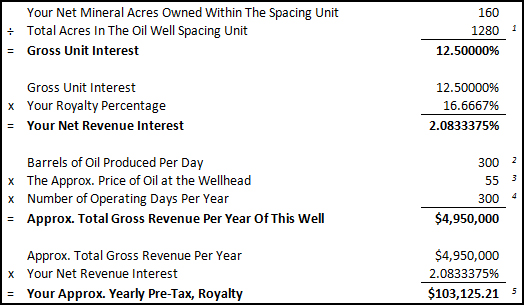

How Can I Estimate Royalties?

Royalties can be estimated quite simply if you know some basic information

1. How many net mineral acres do you own?

2. How many acres are in the spacing unit of the well?

3. What is your royalty percentage?

Take your information and follow the example below. We have used 160 net mineral acres on a 1,280 acre spacing unit with a royalty rate of 1/6 (16.667%) for this example. Of course, this is merely for demonstration purposes. There are many additional factors that may affect your actual royalties.

1-The Spacing Unit is determined by the North Dakota Industrial Commission (NDIC). Horizontal wells are most often spaced on either 640-acre or 1,280-acre units while vertical wells may be spaced on units as small as 40 acres. All spacing units may vary.

2-The amount of oil produced at any given well will vary dramatically. 300 barrels is a very rough average used here for demonstration purposes only.

3-The price of oil at the wellhead is not the same as the futures prices seen on commodities exchanges. Also, due to a lack of pipelines & facilities, most North Dakota oil is discounted for transportation costs. This discount is approximately $8 per barrel but varies depending on the well operator and market conditions.

4-Oil wells frequently do not operate 365 days per year. There is usually some downtime for maintenance and other reasons.

5-State of North Dakota Extraction and Severance taxes will be deducted from your royalty payment. You will also be responsible for federal and state income taxes which will not be deducted.

You may contact your Lessee (the company with whom you signed the lease). They can usually provide contact information for your well. You may also contact the Operator of the well directly. The Operator and their contact information are generally available through your local department or ministry of energy. When calling, you will need to know the owner of record, the land description, and the name of the well if possible.

About The Exploration & Drilling Process

Energy companies make drilling decisions based on geologic and seismic data as well as the history of other wells in an area. When a possible drill site is identified, landmen go to work identifying the legal owners of record and securing leases. The well is then proposed, the Spacing Unit is established, and permits are filed. Finally, the Surface Use Agreement is signed with the surface owner. Now, the site preparation work may begin.

Drill Site SelectionThe selection of the drill site is based largely on the geological evidence indicating the possible accumulation of petroleum. The exploration company will want to drill the well at the most advantageous location for the discovery of oil or gas. Surface conditions, however, must also be taken into consideration when selecting the drill site. There must be a nearly level area of sufficient size on which to erect the drilling rig, excavate reserve pits, and provide storage for all of the materials and equipment that will be required for the drilling program. All of the required legal matters need to have been attended to, such as acquiring a drilling permit, surveying of the drill site, and so on. When all of these matters have been resolved, the work on site preparation will begin.

Photo Courtesy U.S. Dept. of Labor

Drill Site Preparation

Once the drill site has been selected and surveyed, contractors will move in with equipment to prepare the location. If necessary, the site will be cleared and leveled. A large pit will be constructed to contain water for drilling operations and for the disposal of drill cuttings and other waste. A small drilling rig, referred to as a dry-hole digger, will be used to start the main hole. A large-diameter hole will be drilled to a shallow depth and lined with conductor pipe. Sometimes a large, rectangular cellar is excavated around the main bore hole and lined with wood. A smaller-diameter hole called a "rat hole" is drilled near the main bore hole. The rat hole is lined with pipe and is used for the temporary storage of a piece of drilling equipment called the "kelly." When all of this work has been completed, the drilling contractor will move in with the large drilling rig and all the equipment required for the drilling of the well.

Photo Courtesy Nestor Galina

The components of the drilling rig and all necessary equipment are moved onto the location with large, specially equipped trucks. The substructure of the rig is located and leveled over the main bore hole. The mast or derrick is raised over the substructure and the other equipment such as engines, pumps, and rotating and hoisting equipment are aligned and connected. The drill pipe and drill collars are laid out on racks convenient to the rig floor so that they may be hoisted up when needed and connected to the drill bit or added to the drill string. Water and fuel tanks are filled. Additives for the drilling fluid (drilling mud) are stored on location. When all these matters have been attended to, the drilling contractor is ready to begin drilling operations (spud the well).

Spudding In

"Spudding in," or to "spud" a well, means to begin drilling operations. The drill string, consisting of a drill bit, drill collars, drill pipe, and kelly, is assembled and lowered into the conductor pipe. Drilling fluid, better known as drilling mud, is circulated through the kelly and the drill string by means of pipes and flexible hose connecting the drilling fluid or mud pumps and a swivel device attached to the upper end of the kelly. The swivel device enables drilling mud to be circulated while the kelly and drill string are rotated. The mud pump draws fluid from mud tanks or pits located nearby. The drilling mud passes through the kelly, drill pipe, drill collars, and drill bit. It is returned to the surface by means of the well bore and the conductor pipe where it is directed to a device called a shale shaker. The shale shaker separates the drill cuttings and solids from the drilling mud, which is returned to the mud tanks to be circulated again. As the drill string is rotated in the well bore, the drill bit cuts into the rock. The drilling mud lubricates and cools the drill bit and drill string and carries the drill cuttings to the surface.

Photo Courtesy USGS

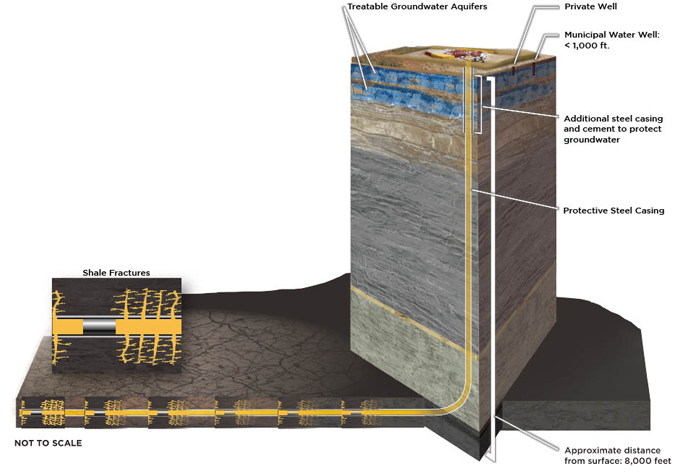

When a well is spud, a large-diameter drill bit is used to drill to a predetermined depth. This is for the purpose of drilling the surface hole. The surface hole is lined with steel casing. The casing protects aquifers which may contain freshwater, provides a mounting place for the blowout preventer, and serves as the support for the production casing that will be placed in the well bore if the drilling program is successful. The surface hole may be several hundred or several thousand feet deep. When the predetermined depth is reached, the drill string will be removed from the well bore. Steel casing of the proper diameter is inserted. Sufficient cement is pumped down the surface casing to fill the space between the outside of the casing and the well bore all the way to the surface. This is to insure the protection of freshwater aquifers and the security of the surface casing. The casing and the cement are tested under high pressure for several hours before drilling operations may be resumed. A piece of equipment known as a blowout preventer is attached at the top of the surface casing. This device is required to control the well in the event that abnormal pressures are encountered in the bore hole that cannot be controlled with drilling fluid. If high-pressure gas or liquid blows the drilling fluid out of the well bore, the blowout preventer can be closed to confine the gas and fluids to the well bore.

Drilling To Total Depth

Drilling To Total DepthAfter the surface casing has been tested and the blowout preventer installed, drilling operations are resumed. They will continue until the well has been drilled to the total depth. Usually, the only interruptions to drilling operations will be to remove the drill string from the well bore for the replacement of the drill bit, a procedure known as tripping, and for the testing of formations for possible occurrences of oil or gas, known as drill-stem testing. Other interruptions may be due to problems incurred while drilling, such as the shearing off of the drill string (known as "twisting off"), and the loss of drill-bit parts in the well bore, known as "junk in the hole."

As drilling operations continue, a geologist constantly examines drill cuttings for signs of oil and gas. Sometimes special equipment known as a mud logger is used to detect the presence of oil or gas in the drill cuttings or drilling fluid. By examining the drill cuttings, the geologist determines the type of rock that the drill bit is penetrating and the geologic formation from which the cuttings are originating.

Today's conventional drill bit utilizes three revolving cones containing teeth or hardened inserts which cut into the rock as the bit revolves. The teeth or inserts chip off fragments of the rock which are carried to the surface with the drilling fluid.

Drill-Stem Testing

Drill-Stem TestingIf the geologist detects the presence of oil or gas in the drill cuttings, a drill-stem test is frequently performed to evaluate the formation or zone from which the oil show was observed. Drill-stem tests may also be performed when the driller observes a decrease in the time required to drill a foot of rock, known as a "drilling break." Since porous rock may be drilled easier and faster than nonporous or less porous rock, a drilling break indicates the presence of porosity, one of the qualities of reservoir rock. A drill-stem test enables the exploration company to obtain a sample of the fluids and gases contained in the formation or interval being tested as well as pressure information, which is determined by special gauges within the test tool.

Drill-stem testing is accomplished by removing the drill string from the bore hole. The drill bit is removed and a drill-stem test tool with a packer is attached. The test tool, packer, and drill string are inserted back into the bore hole to the desired depth. The packer, which is an expandable device, is set and expanded at the predetermined depth to isolate the zone to be tested. The test tool contains a valve which may be opened and closed to allow formation fluids to enter the test tool and drill string. If there is sufficient fluid and pressure within the zone being tested, the formation fluid (oil, gas, water) may rise to the surface and flow into special test tanks used for that purpose. If gas is present, it is burned at the surface as a flare. By analyzing the rate of flow or the amount of formation fluid recovered in the drill string and the formation pressures recorded, obtaining a good indication of reservoir characteristics such as porosity, permeability, and the nature of the fluids or gas contained therein is possible.

Well LoggingDrilling operations continue until the predetermined total depth of the well is reached. A logging company is then called to the well site. The drill string is removed from the well bore to allow the insertion of logging tools, which are lowered all the way to the bottom of the hole by means of a special cable. This cable contains numerous electrical circuits. The tools are reeled slowly back to the surface. Specific properties of the formations are measured as the tools are retrieved. Signals detected by the tools are recorded in a recording truck at the surface by means of the electrical circuits contained in the cable.

Electrical logs measure the natural electric potential and the effect of induced electricity on the formations. Radioactivity logs measure the natural radioactivity and the effect of induced radioactivity on the formations. Sonic logs measure the velocity of sound waves in the formations. By analyzing these logs, experienced geologists and engineers can determine the depth from the surface to various formations and intervals, formation characteristics such as rock type and porosity, and indications of the presence of oil or gas and quantity.

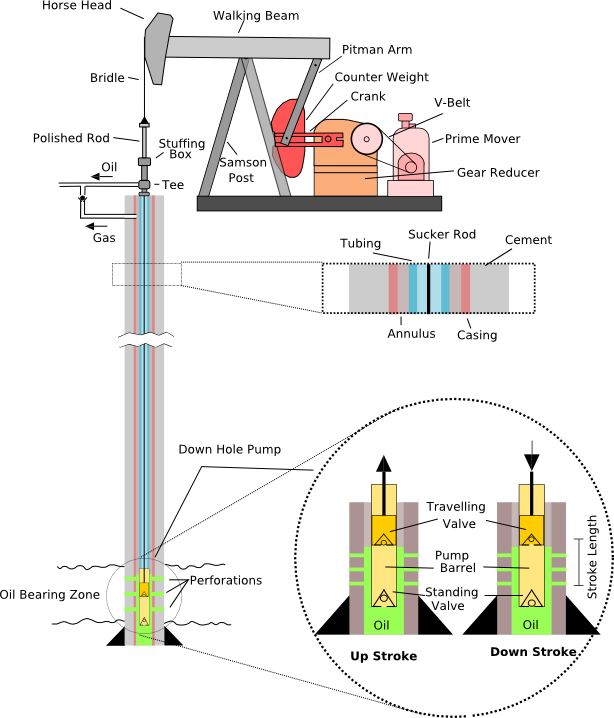

Diagram Courtesy of TastyCakes on English Wikipedia

When drill-stem testing and well-logging operations have been completed and the results have been analyzed, the company management must decide whether to complete the well as a producing well or to plug it as a dry hole. If the evidence indicates that no oil or gas are present, or they are not present in sufficient quantity to allow for the recovery of drilling, completion, and production costs and provide a profit on investment, the well will probably be plugged and abandoned as a dry hole. If, on the other hand, evidence indicates the presence of oil or gas in sufficient quantity to allow the recovery of these costs and provide a profit to the company, an attempt will be made to complete the well as a producer.

If a decision is made to attempt to complete the well as a producer, casing is delivered to the site and a cementing company is called. The well bore is filled with drilling fluid that contains additives to prevent corrosion of the casing and to prevent the movement of the fluid from the well bore into the surrounding rock. The casing is threaded together and inserted into the well bore much in the same manner as the drill string. Casing may be inserted to a total depth of the hole or a cement plug may have been set at a specific depth and the casing set on top of it. Cement is mixed at the surface just as if the well were to be plugged. The cement is then pumped down the casing and displaced out of the bottom with drilling fluid or water. The cement then flows up and around the casing, filling the space between the casing and the well bore to a predetermined height. Special tools are sometimes used with the casing, which allow the setting of cement between the outside of the casing and the well bore at specific intervals. This is done to protect the casing and to prevent the movement of formation fluids from one formation to another.

Photo Courtesy Hydraulic Fracturing Facts

Frac jobs or fracking is a process that results in the creation of fractures in rocks. The most important industrial use is in stimulating oil and gas wells, where hydraulic fracturing has been used for over 60 years in more than one million wells. The fracturing is done from a wellbore drilled into reservoir rock formations to enhance oil and natural gas recovery. Hydraulic fractures may be natural or man-made and are extended by internal fluid pressure which opens the fracture and causes it to grow into the rock.

Man-made fluid-driven fractures are formed at depth in a borehole and extend into targeted rock formations. The fracture width is typically maintained after the injection by introducing a proppant into the injected fluid. Proppant is a material, such as grains of sand, ceramic, or other particulates that prevent the fractures from closing when the injection is stopped. Most Bakken and Williston Basin oil and gas wells depend heavily on fracking due to the poor permeability of most rock formations in the area. Without fracking, Williston Basin oil production will diminish considerably.